The CNC Direct

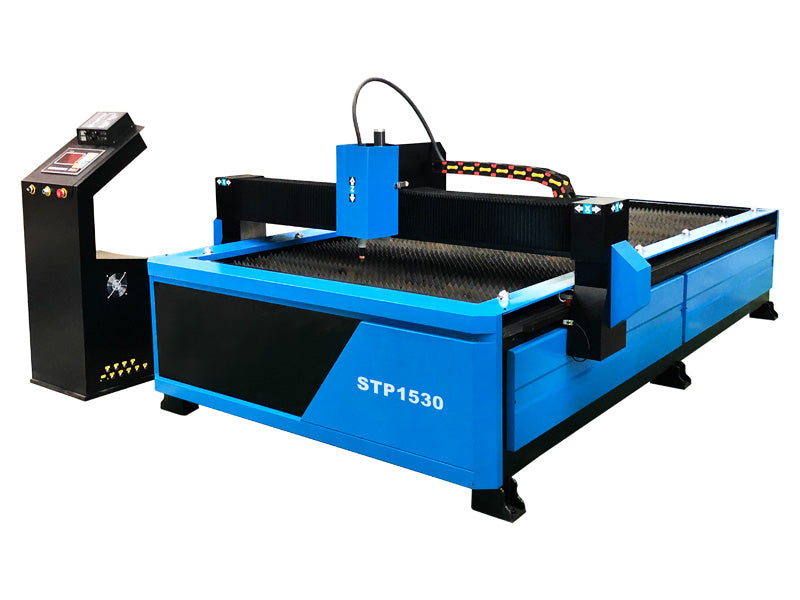

High Definition CNC Plasma Cutter for Metal Fabrication

High Definition CNC Plasma Cutter for Metal Fabrication

Couldn't load pickup availability

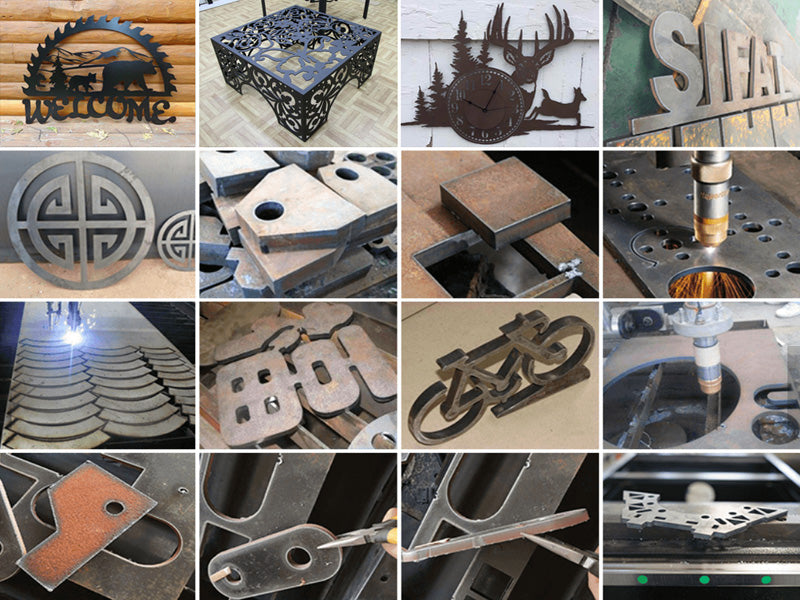

High-definition CNC plasma cutters are cutting instruments that use plasma, a superheated ionized gas, to produce precise cuts in metals. These devices are widely used in industries that require high accuracy, such as metal fabrication, automotive, and manufacturing. High-definition plasma cutters make cleaner, smoother cuts with less waste than traditional plasma cutters.

Operators can program intricate designs into these machines thanks to CNC (Computer Numerical Control) technology. Once programmed, the machine can cut consistently without human intervention. This increases manufacturing efficiency and guarantees that every cut meets the needed criteria.

A variety of metals, such as copper, aluminum, and steel, can be cut with high-definition plasma cutters. They save time and money by reducing the need for additional finishing stages thanks to their accuracy and rapid cutting speed. These gadgets are essential equipment for metalworking businesses trying to boost productivity and enhance product quality.

Features of High-Definition CNC Plasma Cutter for Sheet Metal Manufacturing

1. Welded structure of thickening square tube, together with top brand guide rail to ensure high running speed and accuracy.

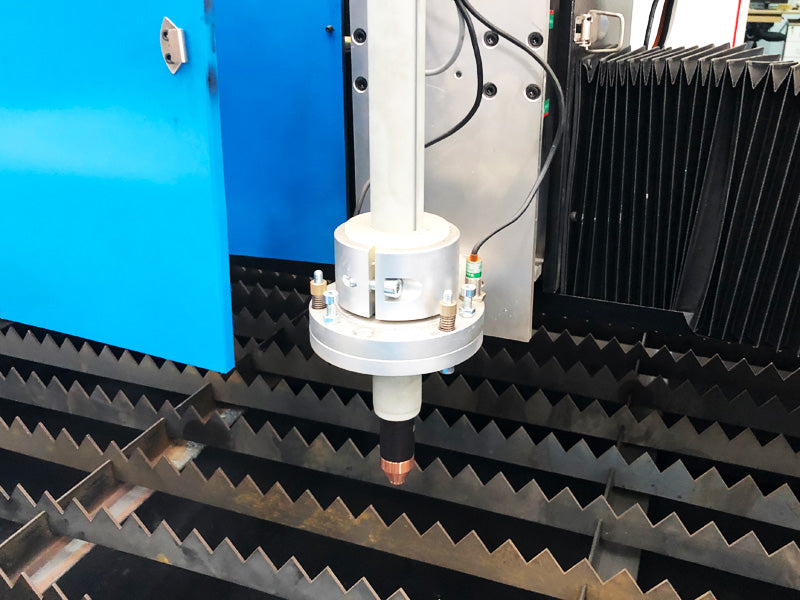

2. Hypertherm plasma power supply together with a highly sensitive arc pressure adjuster. Self-adjusting can choose the best distance between the plasma gun and the working piece automatically to ensure high-accuracy cutting.

3. High definition CNC pasma cutter for sheet metal uses STARFIRE control system with FastCAM software for auto material saving function, large capacity storing function, convenient to read and process.

4. The plasma cutting torch with a professional cooling system can quickly cool the surface of the material to avoid burr and residue.

5. The high-precision rack and pinion driven stepper motor allows the CNC plasma cutting machine to operate with low noise, smooth movement and precise coordinate positioning.

6. Perfect software compatibility, such as Ucancam, Type3, and ArtCAM.

Share